The Three-Legged Stool

Sometimes despite your best efforts and a lot of hard work you don’t get the expected results when working on continuous improvement. This can be very frustrating, especially when you are new to Lean Six Sigma. Imagine yourself in each of the following three scenarios.

Scenario 1: Your company has offered you the opportunity to build upon existing knowledge and experience to improve the business. That’s right – you’re going to become a Lean Six Sigma Black Belt.

After the first week of BB class you return to the office and are excited. This LSS stuff is really cool and your head is spinning with ideas on how to improve different processes. You set a meeting with your manager to discuss where to focus, but she can’t commit this week.

Undeterred, you decide to pull together current performance metrics in preparation for a later meeting. Another week goes by — still no commitment. Just before starting Week 2 of the BB class you reach out to your manager again. She indicates this might not be the best time for change. “Try Steve’s department – he needs help.”

The guidance is appreciated, and after completing Week 2 you send a meeting request to Steve. He is slow to respond. You decide to stop by his office. “I’d like to hear more about this, but we’re swamped. I want to improve, but now’s not the right time. Emily’s department is killing us. Emily…she needs a call.”

Interesting. Emily works in an area where you have limited knowledge. A chance to learn something new! You contact Emily to set up a time to discuss a LSS project. “Lean Six what? We don’t need any of that.” Strike three! Now, frustration sets in. You have so many tools at your disposal, and you’re ready to engage, but you can’t get any traction.

After the Black Belt class wraps up you realize you’ve just spent the past four months learning tons of tools and ingesting loads of information at a rate that can be best characterized as drinking water from a fire hose. You took the final exam, and success…you only missed one (it was that treacherous unit of measure at it again!).

At the beginning of the BB class you were excited about the possibilities. You were going to make a difference! Now you are frustrated and unsure of what to do. What went wrong?

Scenario 2: You are in a management position and have been tasked by the board of directors to make significant improvements to the business. You leverage your knowledge of strategic planning to work with other managers in developing a vision, mission, and top objectives. Then you put together an action plan to have monthly meetings to communicate the state of the business to all employees.

Teams are identified, leaders assigned, and employees are excited about being a part of building a better future for the company, themselves, and their families. During the Process Excellence kickoff session, the air is electric, and everybody is onboard.

As project teams begin meeting you pop in to check on their progress. What you find is staggering. Teams are meeting, they’re gung-ho but seem unsure on what to do. A few have ideas, but most don’t know where to start, and others spend time catching up on social media posts. You ask yourself: “How can this be? Everyone is onboard. Everyone is on fire for making improvements! What in the world is going on?”

Scenario 3: Your company has been struggling with poor quality and productivity. As the quality manager you are charged with improving business results. You convince the management team the company needs to get more systematic in how you operate. To formalize this approach the company decides to implement a well-known quality management system standard.

You start by meeting with managers and supervisors, and everyone agrees having a system in place for process control and oversight will be great for not only quality but also the company’s bottom line. Teams start documenting, mapping, measuring, and recording. Procedures, work instructions, forms, process maps, and audit plans are constructed. You’re on your way. After months of hard work, the company finally achieves registration to the standard. A big party is held to celebrate, and a press release is sent out.

The following quarter comes and goes with no improvement in key results. The next quarter…same story. Uh oh! There’s blood in the water. Employees, managers, and supervisors, and—lookout—members of top management, are all asking why so much time and money was spent building this management system. Where’s the bang for all those bucks?

What is missing in each scenario? In Scenario 1, you had all the necessary LSS tools at your fingertips but nothing to show for that knowledge. Scenario 2 found you with a company culture on fire for improvement…everyone was all-in! Still no results. Enter Scenario 3—you’ve implemented a management system to run the company. Again, no results. So, again, what is missing?

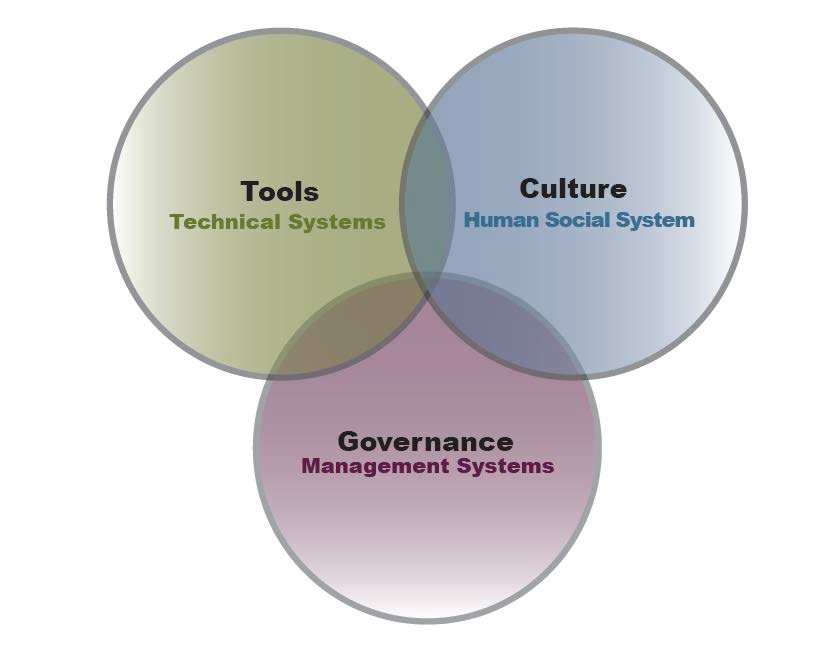

Simple. Each scenario is missing the other two elements to achieve sustainable results. Like the legs of a stool, each is critical to maintain stability and balance. Without all three legs the stool will fall.

The model for sustainable results can be shown with these three legs as:

Sustainable Results = Tools x Culture x Governance

Basic rules of multiplication dictate that any time a figure is multiplied by zero, the product is zero.

Therefore:

Tools x Culture x 0 = 0 Sustainable Results

Tools x 0 x Governance = 0 Sustainable Results

0 x Culture x Governance = 0 Sustainable Results

“Ok, Mike, so you have my attention! I don’t want to experience any of these scenarios. We must have sustainable results. What do I need to do to be successful?”

While the formula is simple, there is nothing easy about it.

Some questions to ponder:

- What is the corporate vision? Are objectives in place that guide the organization toward that vision? And do employees understand the objectives and how they link to the vision?

- Do we have a culture where employees have a sense of ownership of the business? Do we truly value workforce intelligence and input? Do we actively engage employees in not only running but also improving the business?

- Do we have a formal system in place for managing processes? For measuring performance? For maintaining control?

- Do we have the technical “know-how” and the skills needed to drive continuous performance improvement? Do we require improvement as an organization?

- Are we—everybody—always willing to commit to continuously improving business results?

Sustainable results are attainable, but there are no short cuts. Develop the culture. Build the systems. Apply the tools. Enjoy the journey!