Nosco

The Reinvention of Nosco

Nosco has been in business for more than one hundred years, founded in 1906 as the National Office & Supply Company. They are primarily focused on the highly sensitive pharmaceutical packaging market. However, they also provide a breadth of products and services for the nutraceutical and personal care packaging sectors. Nosco has been employee-owned for five years. It is one of only five hundred 100% employee-owned companies in the U.S. Employees have a vested interest in the long-term success of the business and have the enhanced ability to invest in new equipment, technology, and long-term initiatives.

The Situation

Through the years, Nosco had to reinvent itself. They believed in Lean Enterprise as a system that could take them wherever they needed to go. The pharmaceutical industry was going through a period of consolidation, with the small-to-medium clients of Nosco being rolled up into big pharma. The emphasis on price and value versus service drove Nosco to seek new solutions. Nosco turned to TMAC, the Manufacturing Extension Partnership (MEP) Center for Texas, to lead their transformation.

Director of Operations, Brad Elledge acknowledges a lot of companies get hung up on improvement tools. What differentiates a successful Lean Enterprise deployment is involving every level of employee from the top down. Nosco already had a robust quality system as evidenced by their Rx Quality Lifestyle mission statement. The culture of quality embedded at Nosco has become a moral and ethical foundation for its entire operations.

The Solution

All personnel at the Nosco Carrollton facility participated in Lean Enterprise boot camps. It was deployed in groups over time which included Value Stream Mapping, Cellular Manufacturing, Kanban, Lean Office and a variety of other Lean tools. Nosco is now able to boast an 80% reduction in work in process (WIP). Raw material inventory has been reduced by 50% with total inventory turns improving dramatically at the same time. Market conditions made for a very compelling reason for employees to believe in implementing a Lean Enterprise system for sustainability and growth. The results show the difference.

All personnel at the Nosco Carrollton facility participated in Lean Enterprise boot camps. It was deployed in groups over time which included Value Stream Mapping, Cellular Manufacturing, Kanban, Lean Office and a variety of other Lean tools. Nosco is now able to boast an 80% reduction in work in process (WIP). Raw material inventory has been reduced by 50% with total inventory turns improving dramatically at the same time. Market conditions made for a very compelling reason for employees to believe in implementing a Lean Enterprise system for sustainability and growth. The results show the difference.

Nosco sales exceed $80M. Across all three plants they calculate waste elimination of $1M-1.5M per year over the past 3 years. This has been critical given the market price pressure prevalent in the industry in recent years. With the quality and Lean systems in place, Nosco has been able to not only survive, but thrive while experiencing only modest sales increases.

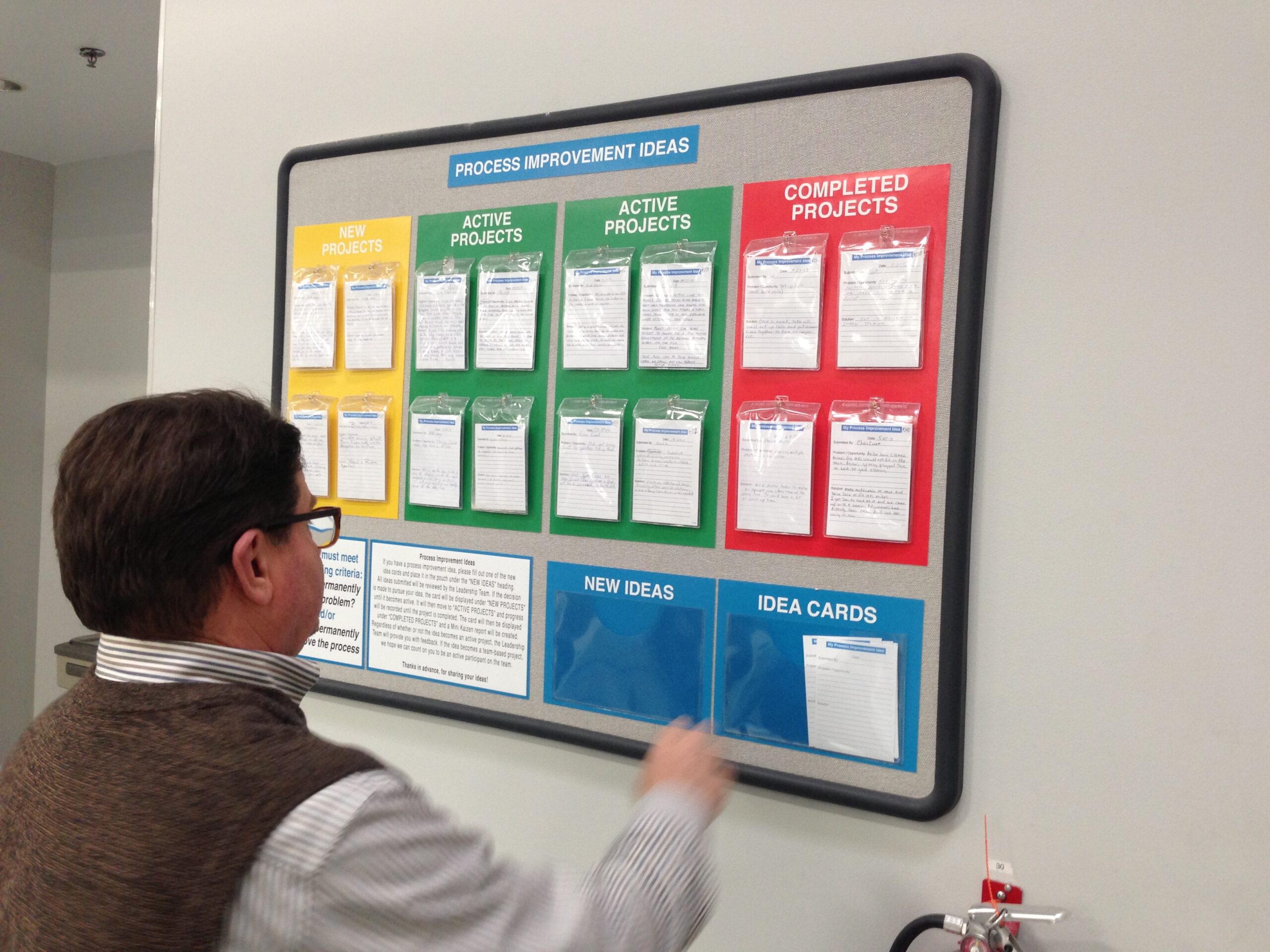

Nosco Carrollton now enjoys a reputation as one of the premier label printing plants in the nation. They make a tremendous impression when audited by their pharmaceutical customers. Visual workplace boards are commonplace and the workplace organization of 5S Lean tools keep areas clean and operating at a high level of efficiency. Nosco’s marketplace requires a great deal of documentation and attention to detail. Implementing Lean Enterprise at all levels and in all departments helps keep this attention to detail at the forefront.

The Results

An $80M company, Nosco was obliged to make price concessions totaling nearly $2M in order to preserve long standing customer relationships. Overall, though our Lean initiative and other cost savings projects, we were able to recover over 75% of those concessions. Nosco operations have been able to generate cost savings company-wide on this scale for the past three years!

Nosco is a firm believer in the MEP/TMAC program and their level of expertise. TMAC worked with Nosco to become the efficient manufacturer they needed to be in a more highly competitive market landscape. Nosco is positioned for continued growth and they have the foundation and infrastructure to sustain it. Change is never easy, but now they wouldn’t have it any other way.

[dt_sc_testimonial name=”Brad Elledge” role=”Director of Operations” image=”https://sixsigma.jacszen.com/wp-content/uploads/2015/01/Wolters.png”][dt_sc_hr_invisible]Lean Enterprise deployment and Six Sigma training have given our people a voice and they’ve practiced using that voice for the betterment of the business. Nosco is a firm believer in the MEP/TMAC program and their level of expertise.[/dt_sc_testimonial]