Creating an Army of Problem Solvers

by Jim Logan

Again this month, we welcome back Jim Logan, a TMAC customer who has worked in a variety of manufacturing industries including automotive, aerospace, oil & gas, medical devices, and high-precision semiconductor equipment. While he has primarily worked in management over the past 15 years, he is equally adept in a technical setting. Jim is also skilled at training and is a LSS Master Black Belt.

The Scientific Method as the Foundation

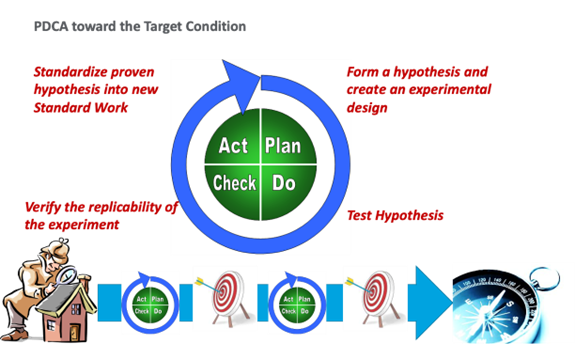

One of the primary reasons I was drawn to Lean Six Sigma is its disciplined reliance on the Scientific Method. Whether through Lean’s PDCA (Plan–Do–Check–Act) cycle or Six Sigma’s DMAIC (Define–Measure–Analyze–Improve–Control) framework, the core principle is the same: structured, evidence-based problem solving.

While mention of the Scientific Method may cause some to disengage, it is critical to acknowledge this foundation. And to consider the alternative: Decision-making and problem-solving based on hearsay, conjecture, and opinion. Many of us have worked at companies with this type of culture. The negative consequences of such thinking include nagging, ongoing problems that are never truly solved, a mindset of finger-pointing and blaming, and the inability to achieve strategic objectives. But worse than all that is a lack of development of people.

Companies that embrace the Scientific Method find it provides the discipline required not only to solve problems effectively but also to cultivate people into thinkers and innovators. This is the essence of building an organization with a culture of problem solvers.

A Pragmatic Business Perspective

There are those who advocate for talent development as simply “the right thing to do.” While I agree with that perspective, I take a more pragmatic view. For any organization operating in today’s competitive marketplace, profitability and value creation are paramount. The single greatest driver of both is not technology, equipment, or even strategy—it is a motivated and capable workforce.

I learned this lesson early in my career as a Plant Manager of an automotive tier-1supplier facility recently acquired out of bankruptcy. The plant faced numerous challenges, but the most pressing issue was the erosion of talent. The original workforce had dispersed, leaving behind a team unable to diagnose and resolve problems effectively. Despite significant investment in training, progress was minimal.

The turning point came when we began to recruit new talent and provide them with structured training. Engagement rose, motivation increased, and solutions began to emerge. Over time, the team not only addressed chronic issues but also drove performance gains that allowed us to transition from a 24/7 operation to two eight-hour shifts, five days a week—while simultaneously improving quality, lowering costs, and increasing profitability.

Three factors made this transformation possible:

- Automotive Rigor: As an automotive supplier our customers required thorough root cause analysis and corrective action for every quality issue. Most required what they termed an 8-D process to direct critical thinking to get to true Root Cause. NOTE: The 8-D Process is a structured approach to problem-solving developed at Ford Motor Company in the 1980s. It has a lot of similarities to the DMAIC process. Here is a link with more on 8-D.

- Lean Immersion: I had spent a year in Japan studying Lean methods firsthand, complementing years of PDCA practice. In PDCA you create a hypothesis and then perform experimentation to prove or disprove your hypothesis. So, during the team building sessions we would use that format to identify potential sources of the quality escapes or production inefficiencies. If our experiment didn’t confirm the hypothesis we moved to the next potential source.

- Six Sigma Discipline: While leading the facility, I earned my Six Sigma Black Belt, reinforcing the rigor of structured problem solving.

The outcome was clear: When employees are trained and empowered, they evolve into proactive problem-solvers who deliver measurable results.

From Training to Application

Later in my career at Halliburton, I observed another dynamic. The company was investing over half a million dollars annually in Lean training. However, the return on this investment was negligible. The reason was simple: Employees were learning concepts but had no direction on how to apply them.

To close this gap, I instituted a new standard. Every participant in Lean training was required to identify a significant business problem within their functional area, secure manager alignment, and then use the tools to address it during the course. Successful completion of the program included a formal project report-out and demonstrated results. This shift turned training from a theoretical exercise into a value-generating process. Across the organization, we began to see measurable quality and efficiency gains that translated directly into financial performance. Halliburton had done a good job identifying their high-performance talent as the individuals to go through the training.

By adding a few simple requirements to the training it insured that these new skills of problem identification, problem solving, and communication of the solution would become ingrained in the future leadership of the organization

The Strategic Value of Talent Development

A common trap for managers is the belief that they must personally solve every problem. But the most effective leaders understand they must invest in developing an organization capable of solving problems at every level.

When employees are trained, empowered, and encouraged to think critically, the results are exponential. Problems are identified and resolved before they escalate. Opportunities for improvement are surfaced organically. The organization becomes agile, resilient, and focused on continuous improvement.

In today’s business environment, no piece of equipment or system upgrade can match the value of an empowered workforce. Creating an army of problem solvers is not simply a leadership philosophy—it is a strategic imperative.