Stability vs. Disruption

Disruption is a very trendy word. Articles about disruptive products, technologies, and services are increasingly common in business magazines. This is especially true in some industries such as consumer electronics and entertainment. Recently I even saw a Linkedin profile of an individual who described himself as a ‘disruptive change agent’. Makes you wonder how he acts during lunch…

What is disruption? Here are definitions from three sources:

- A rending asunder; a bursting apart; forcible separation or division into parts; dilacerations (The Century Dictionary)

- An event that results in a displacement or discontinuity (Wordnet 3.0)

- An interruption to the regular flow or sequence of something (Wiktionary)

Ouch – that first definition sounds painful! Not sure I want to experience that type of disruption.

At the enterprise level disruption implies changes that are strategic in nature. Such changes are much bigger, more complex, and require more resources than typical Lean Six Sigma projects, which tend to be more tactical. Put differently, LSS projects tend to enable strategy but don’t establish strategy.

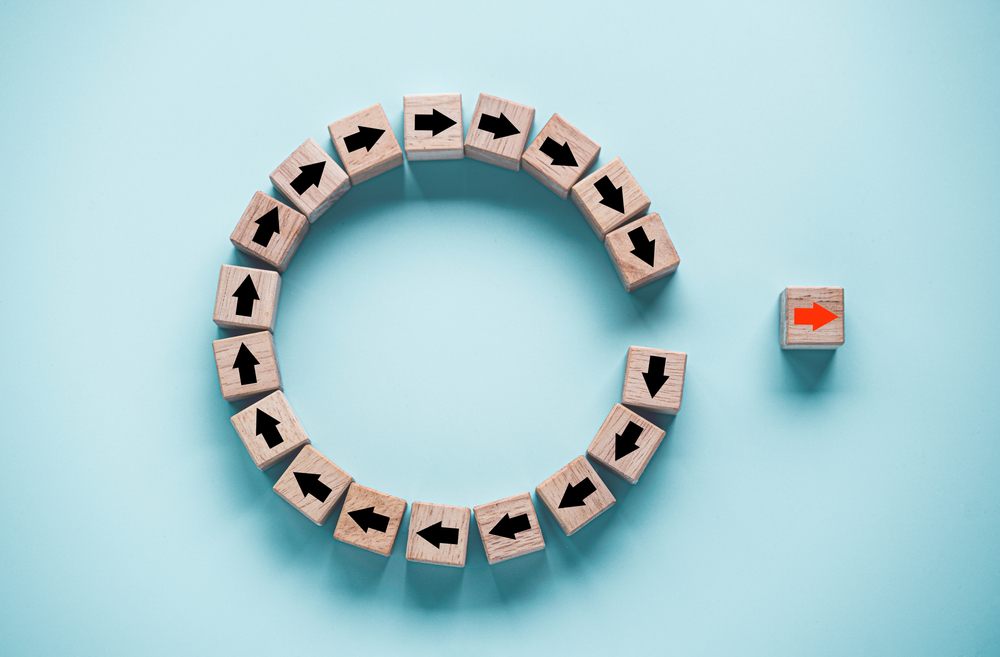

Although the focus of this blog is on LSS projects I will add that at the enterprise level all organizations seek to strike a balance between disruption (some prefer a different word – innovation) and stability. In terms of existing products and services, companies prefer stable processes that yield consistent, repeatable outcomes that meet customer requirements. In addition, the best companies seek to offer features, functions, or other outcomes that make it difficult to be disrupted by competitors.

Balancing stability (of existing products and services) with disruption (of new products and services) is key to any healthy business enterprise. To do otherwise is to invite complacency, which is never a good thing. In many cases market forces require a firm to offer new items or services simply to keep up with the competition. Done correctly, disruption can help a firm take away market share from their competitors.

Back to a Lean Six Sigma focus: The overarching assumption in the LSS world is that senior management sets strategy, whereas Green Belts, Black Belts, and Master Black Belts work to execute or enable the strategy by performing process improvements. The only caveat to this approach: If a firm utilizes not just Lean Six Sigma but also Design for Lean Six Sigma. In the case of DFLSS there is a potential to create new products, processes, or services which can be dramatically better than the competition. And hence, disrupt the marketplace.

Now let’s examine the three ways of defining disruption shown above. I believe the concept of disruption as described in definitions 2 and 3 above are consistent with the DMAIC process. Consider that during the Improve Phase it is considered a best practice to perform a pilot. By their very nature most pilots will result in ‘displacement’, ‘discontinuity’, or ‘interruption’ of a process. In essence, the goal of a pilot is to ‘disrupt’ the current process in such a way that the ‘new’ process yields improved outputs.

How do you think a pilot feels to front-line staff? They may very well perceive the LSS process improvements as being consistent with definition 1 – ‘a forcible separation’ or ‘a bursting apart’ or even ‘rending asunder’. This is the reason why it is so important to involve these individuals in not only the development of these solutions but also in the implementation. Put differently, all effective LSS practitioners set aside time for change management.

Once the improvement (i.e., the disruption) is fully implemented, the goal of management is to achieve stability in the new, improved process. Stable processes achieve consistency in quality, speed, and cost of products or services. And on a more basic level, stable processes are easier to manage.

So – how do you achieve stability? First, the good news for LSS practitioners is that we have a simple and powerful tool to determine if a process is stable: Control Charts. By using an I-MR or X-Bar R chart (or similar charts) we can determine if a process is in control. That is, measuring stability is relatively easy.

Now to the question of how to achieve stability. Here is where our Lean Toolkit provides so many options. A list of lean methods which help to establish stability includes but is not limited to:

- Standard Work / Checklists

- Leader Standard Work

- 5S / Visual Management

- Generic Pull / WIP Cap

- Replenishment Pull (Kanban)

- One-piece Flow

- Point-of-use Storage

- Takt Time / Line Balancing

- Mistake Proofing / Poka Yoke

- TWI Job Instruction

In conclusion – all successful LSS projects require a degree of both disruption and stability. The careful balance of these two goals is not easy, but is part of effective project management for all LSS practitioners.

Good luck on your next project!