Customer Spotlight: Amy Hogan, Setpoint/PVI Holdings by Russ Aikman

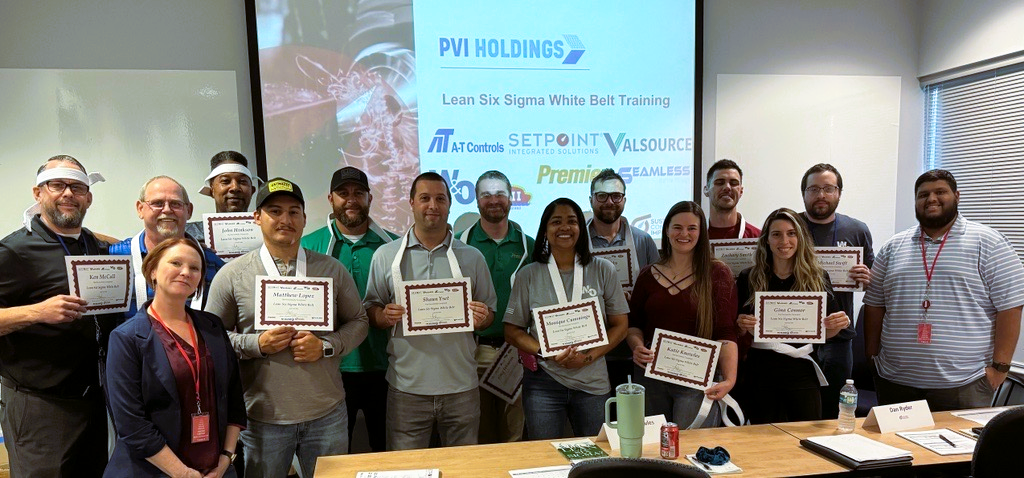

This month’s newsletter is one in a series about individuals working in continuous improvement. We asked LSS practitioners to tell their stories and share lessons learned. This month’s spotlight is Amy Hogan, a LSS Black Belt with Setpoint Integrated Solutions which is owned by PVI Holdings. Amy completed her GB training in 2017 and BB training in 2020. Setpoint Integrated Solutions is the expert in the process control industry, serving the power, refining, and chemical industries with best-in-class valve repair services, delivering process solutions for control, relief, and automated valve requirements, along with industrial equipment. In the LSS photo above, that’s Amy on the right wearing the blue shirt with white sleeves.

Tell us about your career working at Setpoint. When did you begin working there and what was your role? What other departments/areas have you worked in?

I began my career at Setpoint in 2001 and have had the opportunity to gain intimate knowledge of many departments in the organization throughout the years. Initially working in administrative support and inside sales for Pressure Protection products at one of our local branches, I eventually moved to corporate functions gaining exposure through advancement in many different departments including Central Purchasing, ERP projects, Data Management, Business Execution, Sustainable Continuous Improvement, and Integrations.]

How and when did you first get involved in Continuous Improvement/Quality?

During my early years with Setpoint, I had a branch manager ask me to attend two different Lean workshops: Lean for Job Shops and Lean for the Office. The concepts immediately resonated with me, and I began applying the principles to identify and improve bottlenecks in the workflows and communications between shop personnel and sales. A few years later, a former CEO of Setpoint joined the team from a previous role with Dr. Pepper and began to further our interest in continuous improvement by sending me to LSS GB training with TMAC. My enthusiasm for process improvement and ability to use data for problem solving led to my return for LSS BB Training a few years later.

What was your initial reaction when you first learned about Lean Six Sigma?

When first introduced to LSS, the learning of principles to be able to apply proven methods & tools to problem solving I was already doing lit some sparks in me. Another aspect was the emphasis on viewing processes ‘from a customer’s perspective’ as everything we strive to do in our business is for customer satisfaction. I genuinely “geek out” over drilling into issues and understanding what drives certain process steps or behaviors so to tie it all together with a structured approach prompted my interest.

What are your memories of your LSS training. What did you like? Dislike?

The first workshop trainings I attended were one day courses each and what I enjoyed most were the breakout activities we did – a JIT exercise on one-piece flow. Fast forwarding to 2017 TMAC GB training, what I loved most was diving into the DMAIC process. And – the instructors. Memories of the 2020 TMAC BB training are a bit different – we were only able to do 2 of the 4 weeks of training on site in person. After that, COVID moved us to attending class remotely. 8-hour sessions on Teams meetings can be grueling but TMAC did a great job of breaking the classroom context into activities that included interaction. Performing group regression analysis and DOE through Minitab exercises through breakout Teams meetings and waiting rooms were interesting in this format 😊

Can you share a little about your experience as a Black Belt, especially in terms of leading project teams?

My first BB project was a focus on functionally centralizing all AR activities, reducing process cycle times for invoicing and days sales outstanding (DSO) reduction to improve free cash flow. The billing team was being used as a “catch all” at the end of the process to fix the process issues occurring upstream for an error free invoice to go out to the customer – leading to delayed invoicing, unhappy customers and elevated DSO.

One of the toughest but most rewarding exercises in this project was getting the project team together to map their current billing processes. We huddled in a room and spent several hours documenting all the as-is (at the time) siloed process flows. A group of individuals that all had their own reasons of why they “have always done it that way” left with having multiple “AHA!” moments during those hours. After several iterations, we ultimately automated invoicing through the ERP system at time of shipment, improving PCT for invoicing by 50% and improving free cash flow by ~$4M.

This took patience though – and a team! And it was my job to listen more than speak & follow the methods fully — even when some answers seemed so obvious to me personally; I needed to be the guide but allow for the employees to lead the change.

What did you like best about working as a BB? And what was most challenging?

What I’ve liked best about working as a BB is bringing different mindsets, backgrounds & dept personnel into a kaizen or DMAIC project and having everyone work on the same problem but with input from different aspects. Providing others with training to empower them to understand more on how to use data to solve problems.

The most challenging part of working as a BB is understanding that not everyone carries the same passion for improvements or change and sometimes not everyone feels empowered to be part of or make changes. These are two different extremes. In one, employees are perfectly fine with an imperfect, wasteful process. In the other, employees are not fine but don’t know how to go about leading a change. We need to focus on both types of employees equally, but in different ways – and have everyone feel as one integrated team.

Another fond experience as a BB is having the formal CI team partner with Quality for different CI campaigns. 5S campaigns were always fun challenges between sites and celebrating wins is always important.

What are your biggest lessons learned about using Lean Six Sigma? Any tips for new GBs and BBs to help them be successful?

Start small, think achievable at first and don’t get discouraged. My initial GB project was back-office process improvements for the quote to cash process. When looking at that on paper, it could be broken out into 7 different process segments including different departments. It was definitely a multi-generational project that needed to be broken down into more bite-size elements. It’s easy to get eager and try to accomplish grandiose goals but one can get easily overwhelmed and end up being counter-productive with such an approach.

Can you talk about your career since working as a BB at Setpoint?

Since working as a BB at Setpoint I not only worked on several CI projects, but also developed the first formal CI program for the organization. In addition, I managed several CI integration merger/acquisition projects – 6 in total. I now work for Setpoint’s holding company, PVI as VP of Integrations. There are two sister divisions under PVI in addition to Setpoint. In this role, I’m able to expand our LSS CI program to the other divisions and have begun progressing individuals through our training programs. I also spend every day working on how we integrate and standardize processes to be 3 companies with one way of working. I love the process of understanding why processes are written the way they are, identifying where they can be combined & streamlined and spreading the knowledge to others on tools and methods to derive data-driven answers.

Looking back, how has LSS affected your career path?

Lean Six Sigma and CI have been a driving force behind decisions made for my career path. The business roles I held within Setpoint allowed me to run almost full circle through every back-office department, including some exposure to Operations and Warehousing. This let me see the full spectrum of business process flows & how work performed affects departments upstream and downstream in that flow. Adding Lean Six Sigma training into that front-line experience empowered me to excel at breaking down problems and implementing improvements. Building out a structure with a CI program and seeing others progress through similar paths is rewarding. I have a passion for criticizing the process and not the people and putting that to use everyday through integration efforts within departments, across departments, and across companies.

If you are ready to start your own Lean Six Sigma journey, we have classes starting this fall! Find out more and register for our Green Belt, Black Belt, and Accelerated Black Belt fall classes. Hope to see you there!